IXPE / PP yog dab tsi

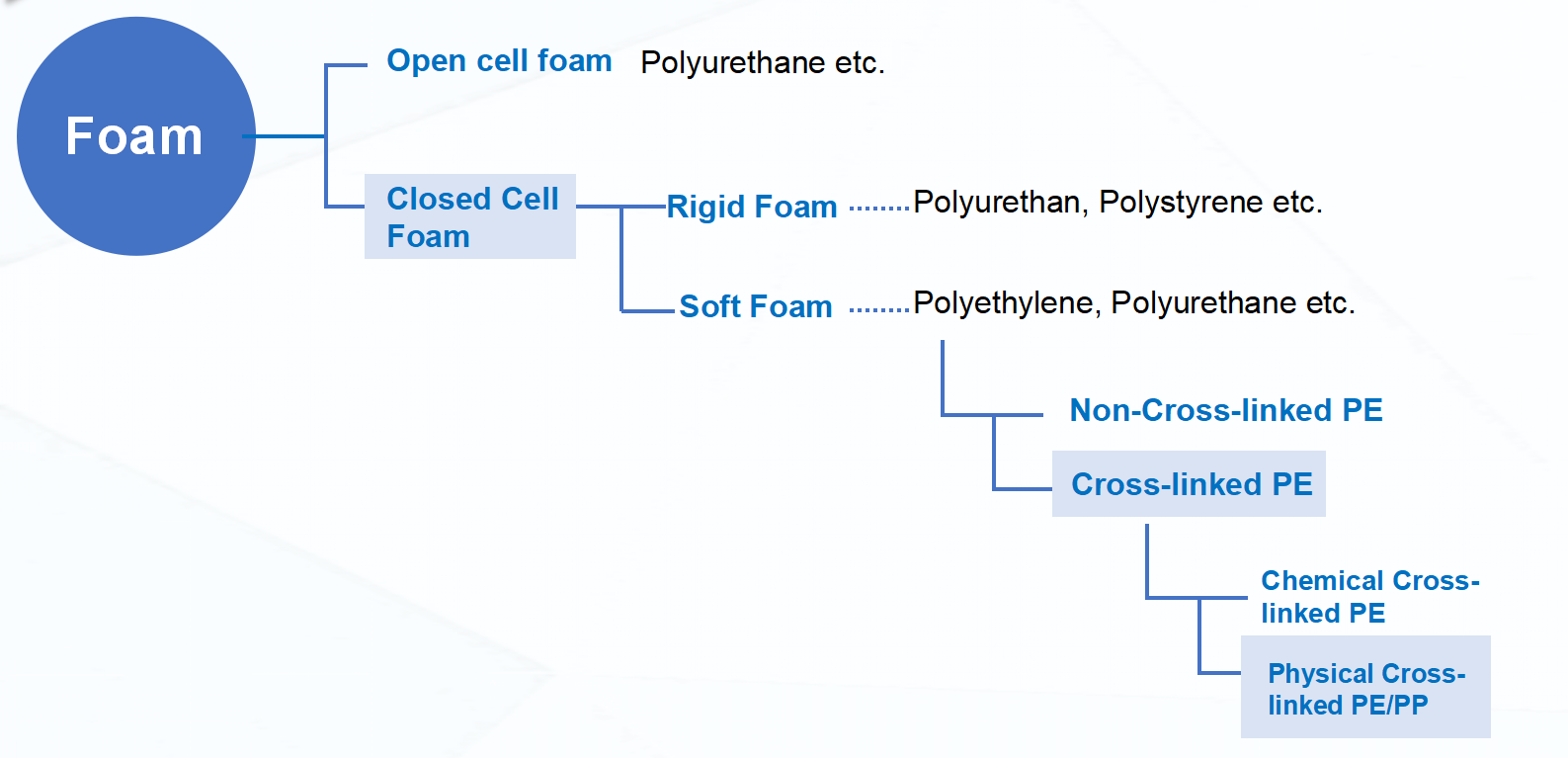

Ua npuas ncauj

Ua Npuas Ncauj yog ib hom khoom yas uas muaj cua npuas tau tawg ua kom nws ntxeem tau.Cov npuas dej muaj ntau cov huab cua thiab yog li lub teeb yuag thiab zoo heev rau cushioning thiab thermal rwb thaiv tsev.

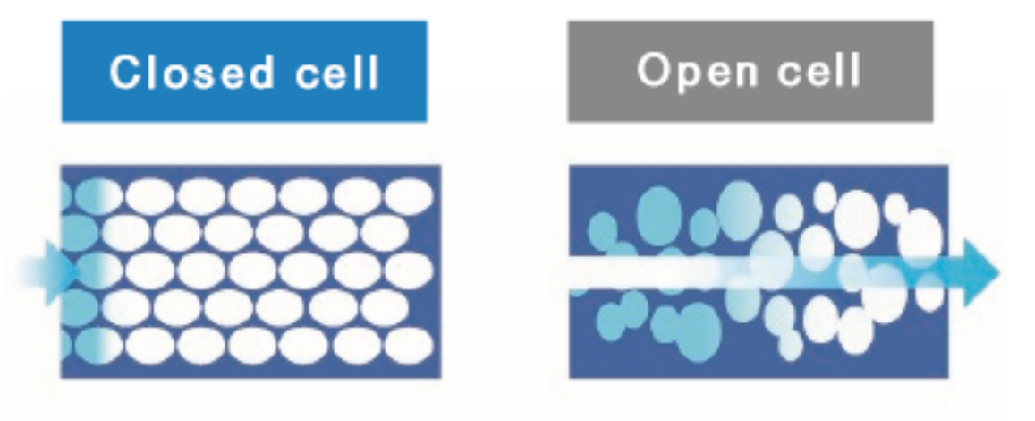

Closed-cell Foam

Hauv cov npuas dej no, cov npuas sab hauv yog ywj siab, tsis txuas rau ib leeg (qhib-cell).Cov hlwb kaw tsis yooj yim tso cua.Yog li, lawv yog bouncy, sai sai rov qab lawv cov qub zoo thaum nias, thiab tiv thaiv dej.

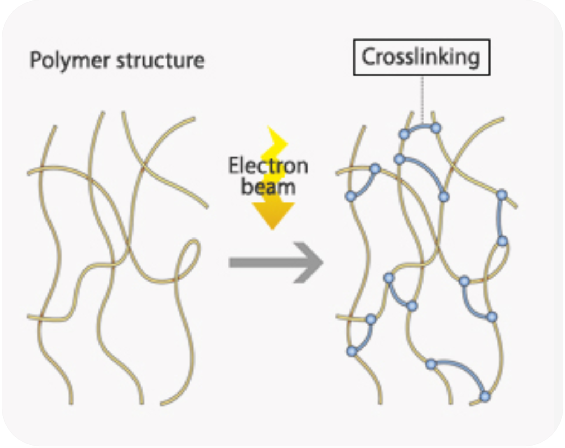

Cross-linked PE

Ib qho tshuaj tiv thaiv uas ua ke nrog polyethylene molecular chains.Crosslinking cov qauv molecular txhim kho lub zog, tiv thaiv tshav kub, tshuaj tiv thaiv, thiab lwm yam. Cov txheej txheem hu ua crosslinking vim tias cov saw hlau ntev molecular zoo li txuas hniav.

Lub cev sib txuas PE / PP

Electron beams rhuav tshem cov ntawv cog lus molecular thiab tsim cov chaw ua haujlwm ntawm cov polymer.Irradiation crosslinking yog ib txoj hauv kev los txuas cov chaw nquag no rau ib leeg.Piv nrog rau cov khoom sib txuas sib txuas, irradiation cross-linked khoom yog ruaj khov thiab sib npaug sib npaug.Qhov zoo muaj xws li qhov muag muag thiab du thiab zoo rau kev tsim xim.

Kev tsim khoom

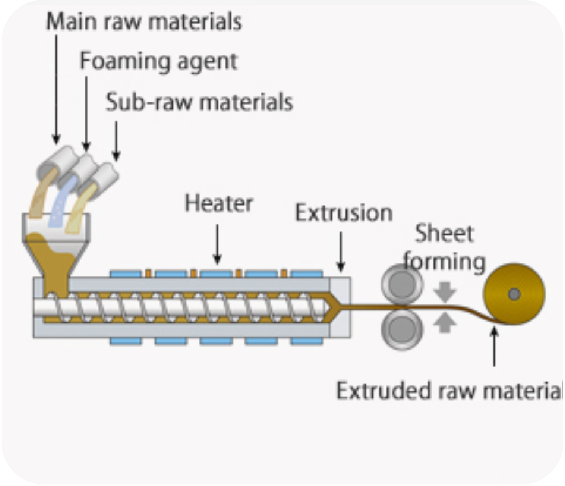

Extrusion

Cov ntaub ntawv raw (PE / PP) yog tov nrog cov tshuab tshuab thiab lwm yam ntaub ntawv thiab extruded rau hauv cov ntawv.

Irradiation

Emitting electron beams ntawm polymers los tsim cov qib molecular bonds.

Ua npuas ncauj

Cov nplooj ntawv yog foamed los ntawm cua sov, tsim ua npuas ncauj nrog ntim txog li 40 zaug.

Dej Resistance / Absorption Strength

Dej Resistance/Absorption

Polyolefin resin-raws li kaw-cell ua npuas ncauj muaj qhov nqus dej tsawg

Txij li polyolefin yog lipophilic resin, nws yog cov khoom siv qis-hygroscopicity.Cov hlwb hauv IXPE / PP tsis txuas nrog, uas tsis tso cai rau dej nkag, nthuav tawm cov dej tsis zoo.

Lub zog

Sturdier tsis tau hloov pauv, nrog cov cua sov ua haujlwm zoo dua thaum piv rau cov npuas tsis sib txuas

Kev sib txuas ntawm cov qauv molecular ntawm polymer nrog cov ntawv cog lus zoo li cov hlua txuas ntxiv kom nruj cov molecular bonds, uas ua rau cov qauv molecular lattice mesh, txhim kho cov cua sov thiab lub zog.

| Crosslinked | Tsis-crosslinked | |

| Expansion Rate | 30 Sijhawm | |

| Thickness | 2 hli | |

| Tensile zog (N / cm2) * 2 | 43 | 55-61 : kuv |

| Elongation (%) * 2 | 204 | 69-80 : kuv |

| Tear Strength (N/cm2) * 2 | 23 | 15-19 : kuv |

| Max Ua Haujlwm Teem * 3 | 80 ℃ | 70 ℃ |

Thermal Conductivity Thermal Insulation Thaum tshav kub kub Resistance

Thermal conductivity

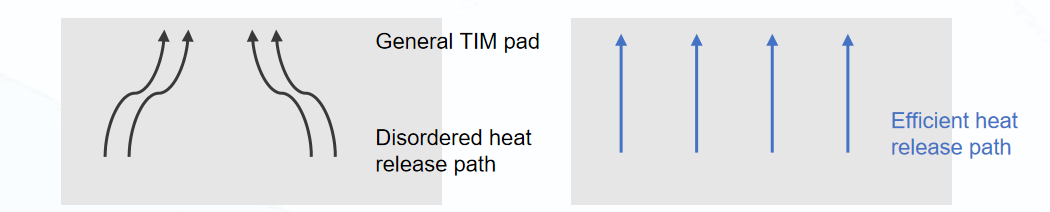

Optimally txheej txheej thermal conductive muab tub lim ua tau siab thermal conductivity

Peb tswj cov kev taw qhia ntawm anisotropic thermal conductive muab tub lim los ua kom muaj cua sov tawm txoj hauv kev, ua tiav cov thermal conductivity thiab softness.Tsis tas li ntawd, peb cov khoom sib xyaw ua ke yog tsim los ntawm cov khoom siv hluav taws xob nkaus xwb thiab cov khoom siv tsis muaj siloxane, txo qhov kev pheej hmoo ntawm kev cuam tshuam cov khoom hluav taws xob mus rau qib qis heev.

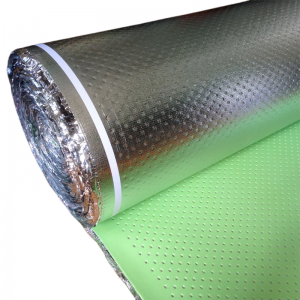

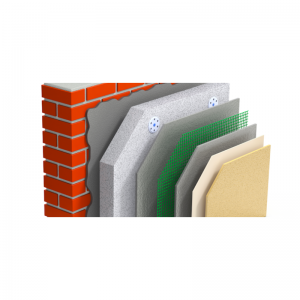

Thermal rwb thaiv tsev

Ua npuas ncauj muaj ntau cov huab cua nrog tsawg convection uas ua rau tsis tshua muaj thermal conductivity thiab superior thermal rwb thaiv tsev kev ua tau zoo

Kaw cov hlwb hauv npuas txwv cov huab cua convection, ua kom sov me ntsis, uas muab thermal rwb thaiv tsev zoo heev.Sib txawv ntawm cov iav ntaub plaub thiab cov ua npuas ncauj nruj, ua npuas ncauj yog qhov hloov tau yooj yim dua thiab yooj yim rau nruab.Yog li ntawd, nws yog tsim rau insulators rau sau qhov chaw me me hauv tsev thiab ntau yam tshuab.

Thaum tshav kub kub Resistance

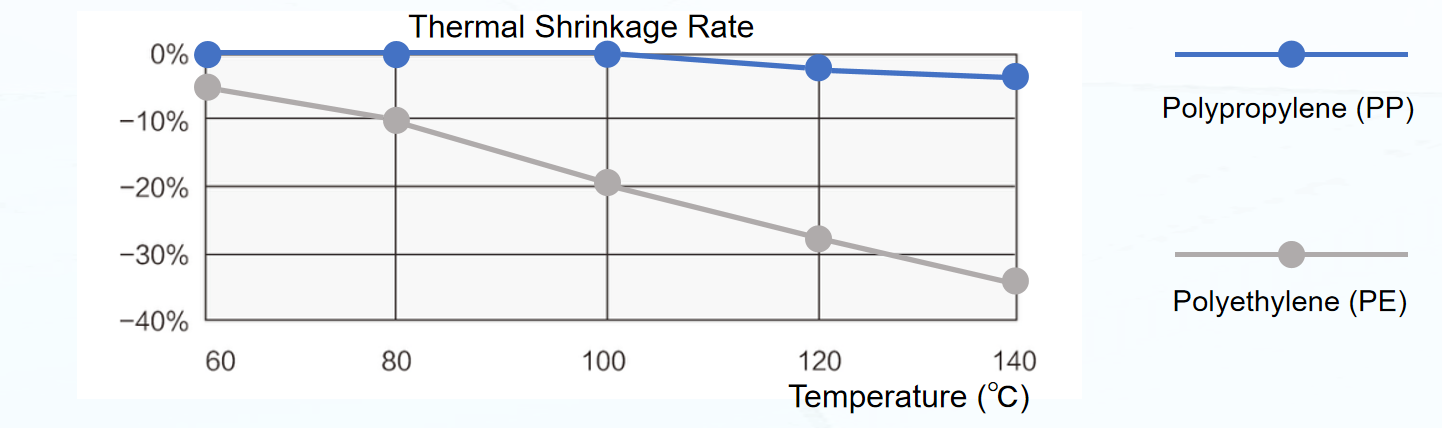

Nrog rau cov cua kub zoo heev, polypropylene resin muaj tsawg thermal shrinkage txawm nyob rau hauv qhov kub thiab txias

Tus nqi sawv cev ntau npaum li cas cov npuas hloov pauv loj ntawm qhov sib txawv ntawm qhov kub thiab txias thaum rhuab yam tsis muaj kev quab yuam sab nraud.Thaum polyethylene ua npuas ncauj deforms thaum rhuab mus rau 80 ° C los yog siab dua, polypropylene ua npuas ncauj muaj zoo heev tshav kub kuj nrog ib tug shrinkage tus nqi ntawm 3% los yog tsawg dua txawm nyob rau ntawm 140 ° C.

Sealing Ability Smoothness Flexibility

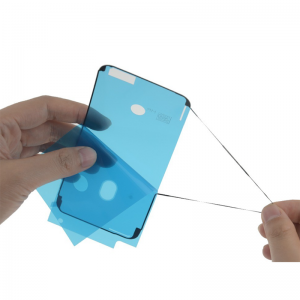

Sealing Muaj peev xwm

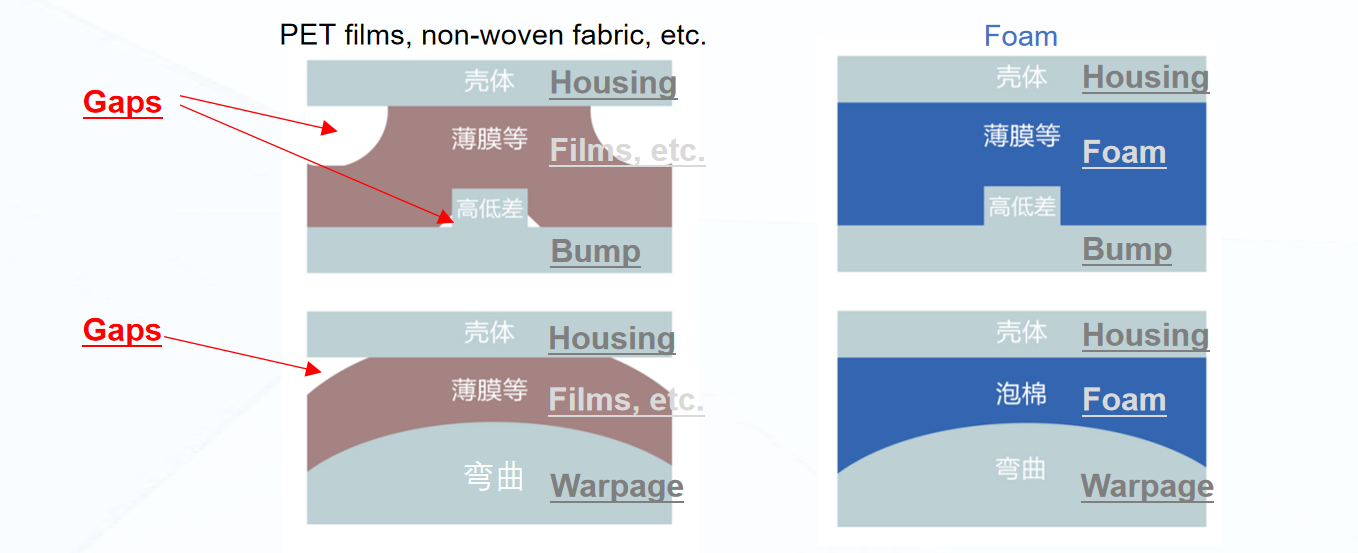

Nrog nws yooj yim, lub npuas seals tsis sib xws los yog ntse nto

Cov cuab yeej sealing ntawm lub sealer xws li tapes yog heev cuam tshuam tsis tsuas yog los ntawm cov khoom ntawm cov khoom siv, tab sis kuj los ntawm nws cov kev sib raug zoo ntawm lub cev nrog lub uneven nto ntawm adherend.Cov khoom siv nrog kev hloov pauv siab tshem tawm qhov tsis sib xws nrog cov adherend thiab paub txog kev ua haujlwm siab sealing.

Sib piv nrog lwm cov ntaub ntawv ntawm cov khoom sib khi

Ua npuas ncauj seals qhov chaw tsis sib xws thiab sau qhov khoob hauv lub tsev

Smoothness

Ib qho yooj yim thiab huv si saum npoo piv rau tshuaj lom neeg crosslinked ua npuas ncauj, haum rau adhesion thiab txheej

Electron beam crosslinking accelerates electrons nrog high voltage thiab emits lawv mus rau nplooj ntawv.Cov nqaj hluav taws xob sib npaug thiab ruaj khov nkag mus los ntawm txhua daim ntawv, ua rau muaj kev sib koom ua ke ntau dua li lwm txoj hauv kev.Nws tso cai rau txawm foaming uas tsim ib tug du nto txheej haum rau adhesion thiab txheej.

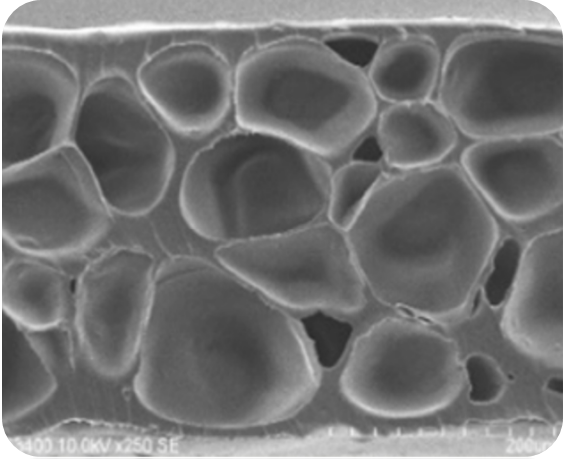

Yooj yim

Resin's intrinsic softness thiab kaw-cell qauv muab tsim nyog elasticity thiab cushioning

Lub cell ntawm electron-crosslinked nplooj ntawv yuav muaj inflate nyob rau hauv cov txheej txheem tom qab foaming.Cells nrog ntau lub sijhawm nthuav dav tsim cov qauv kaw-cell uas txhua lub hlwb raug cais los ntawm phab ntsa.Lub kaw-cell qauv muaj qhov tshwj xeeb cushioning thiab shock absorbing.Muaj kev poob siab zoo heev txawm tias me me thickness, IXPE / PP nplooj ntawv yog siv los ua pob cushioning rau precision instruments.

Ua haujlwm tau

Thermoformability

Tsawg Ib puag ncig Load

Cov yam ntxwv hluav taws xob

Ua haujlwm tau

Zoo heev zoo stability paub ntau yam ua

Siv cov thermoplastic polyolefin resin, peb cov npuas dej tuaj yeem hloov pauv qhov dej ntawm cov polymer los ntawm kev hloov kub.Los ntawm cua sov thiab yaj, nws tuaj yeem txuas lwm cov ntaub ntawv los yog deform ua npuas ncauj.Los ntawm kev ua kom zoo dua ntawm cov duab ruaj khov ntawm chav tsev kub, nws tuaj yeem txiav rau hauv cov duab nyuaj.

Lub ntsiab ua piv txwv

● Slicing (thickness hloov)

● Lamination (kub vuam)

● Tuag txiav (txiav nrog pwm)

●Thermoforming (lub tshuab nqus tsev, xovxwm molding, thiab lwm yam)

Thermoformability

IXPP tiv taus qhov kub thiab txias thaum lub sij hawm molding, ua kom muaj kev sib sib zog nqus nqus

Polypropylene (PP) muaj cov ntsiab lus melting ntau dua li polyethylene (PE).Nrog nws cov cua kub zoo heev txawm tias kub kub thaum lub sij hawm molding, PP tuaj yeem ua tiav ob qho tib si zoo heev thermoformability thiab cushioning.Tshwj xeeb tshaj yog, PP yog dav siv rau tsheb sab hauv trim cov ntaub ntawv thiab cov txiv hmab txiv ntoo tiv thaiv tais.

Tsawg Ib puag ncig Load

Halogen-dawb, tsis muaj pa phem thaum hlawv

Polyolefin yog ib hom yas tau los ntawm kev sib xyaw monomers (piv txwv li chav tsev molecules) nrog carbon-carbon ob daim ntawv cog lus.Txij li thaum nws tsis muaj halogens xws li fluorine thiab chlorine, nws tsis tsim cov pa phem heev thaum hlawv.

Cov yam ntxwv hluav taws xob

Ib tug loj npaum li cas ntawm cov huab cua nyob rau hauv kaw hlwb muab zoo heev dielectric zog thiab permittivity tsawg

Kaw-cell qauv, nyob rau hauv uas huab cua uas tsis muaj dielectric zog yog nyob rau hauv ib tug sib cais me me qhov chaw, exhibits superior dielectric zog.Tsis tas li ntawd, polyolefin, uas muaj qhov permittivity tsawg dua piv rau lwm cov khoom siv dav dav, tsim hauv cov qauv uas muaj huab cua muab kev tso cai qis dua.